Mercator V7

Mercator is a software system for visualizing and controlling complex production processes, especially in the area of laser material processing with the help of industrial robots.

It is also perfect for the usage with robot based manufacturing like adhesive applications or roller hemming. In short it is an easily operated software for all robot applications, which depend on the precise maintenance of speeds and process parameters.

Mercator is a modular, windowed graphical software system. It allows the visualization of robot data as well as its connections with various process data that would be otherwise difficult to access .

With the help of optional modules MERCATOR makes troubleshooting shortened and easier in production processes. The modi-fication of robot programs of Kuka robots, SEF and Fanuc is possible with the module Folgeneditor. By connecting various sensors to the Sikora switchbox diverse sensor applications with the system are possible. In addition, the pro-gram facilitates the daily work with the robot, by supporting determining the TCP or the file management of the robot controller

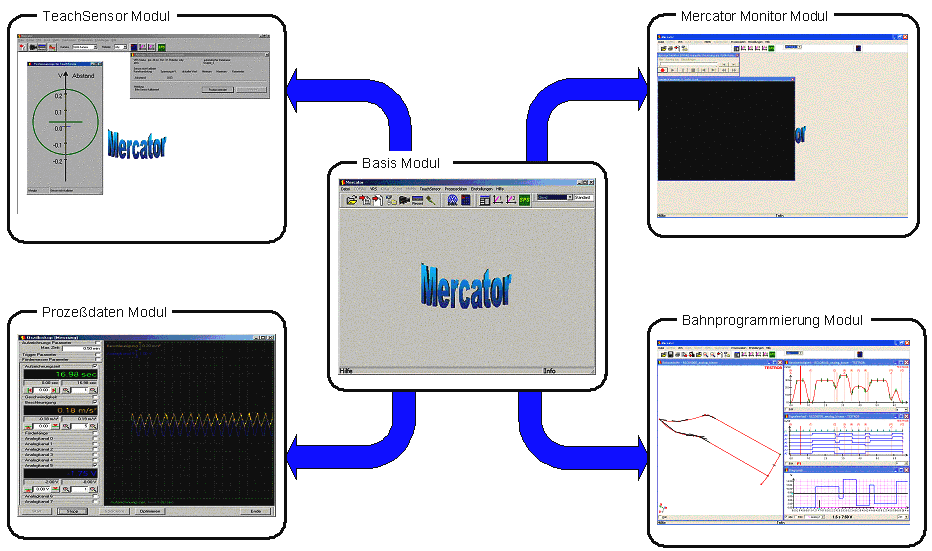

The base module is the basis for every MERCATOR software system. It includes features for representing robot programs in 3D, as well as diagrams of velocities, axis angle and signals.

The other modules, such as Mercator monitor (MeMo) TeachSensor (TS), Prozessdatenerfassung (Process data acquisition), the Folgeneditor as well as the interconnect modules to VRS, VKRC, KRC and Fanuc, deliver application-specific additional functions that can be used according to the acquired configuration. Other modules are in development.

The new version of Mercator (V7.x) also allows remote welding with the PFO and normal welding steps to be conveniently set up and optimized on PC .

Depending on the acquisition of modules, user level and accessory parts (eg Sikora switch box), more menu items and selection boxes in the surface area become available.

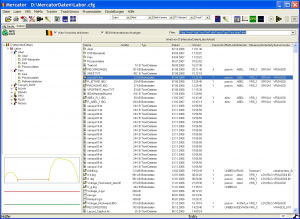

To manage the data of the robot controllers easily, a normal Windows-Explorer-like file viewer was integrated in Mercator.

Mercator Modules:

Mercator Basic Package

Prod.-Nr.: [010-607-01]

Data Sheets: Download-Center

Request for Quote: click here

Function:

The Basic Package provides all basic functions to analyze robot trajectories. These are functions for production line configuration, setup and communication as well as data management.

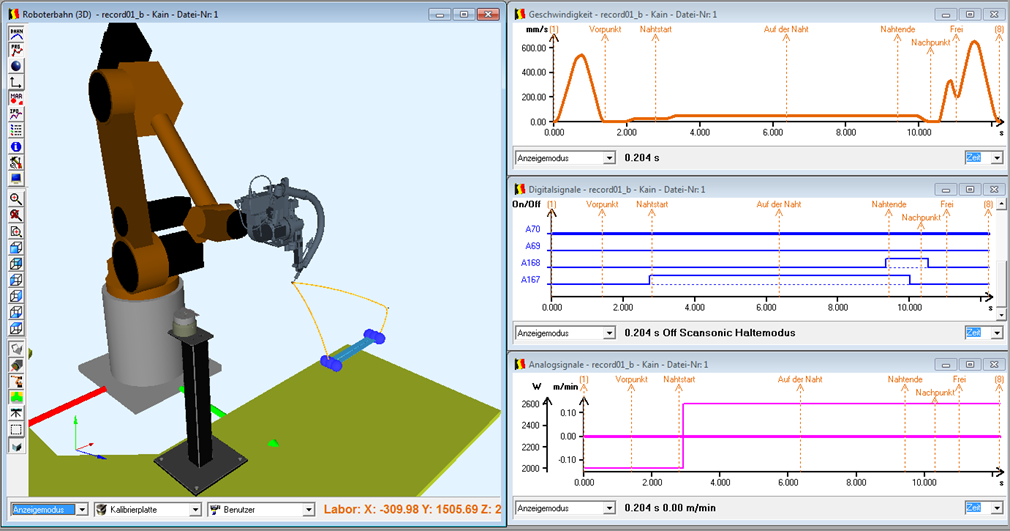

Additionally included are functions of the Mercator Viewer module that allow to display robot position/orientation, speed and signals, each in its own window. The special Four-Window-Technique of Mercator eases analyzing robot programs and IBGN-files by providing a correlated cursor in all windows. Supported robot controls are KUKA, Fanuc and VRS.

IBGN-files are recordings of the robot control status. If the robot control supports IBGN functionality a set of trajectory and signal data is recorded every IPO-cycle of 9 to 15 msec. in ASCII-format which is editable in standard editors. The IPO-cycle is the smallest chronological computing interval of the robot control. The length of the time interval is depending on the respective control.

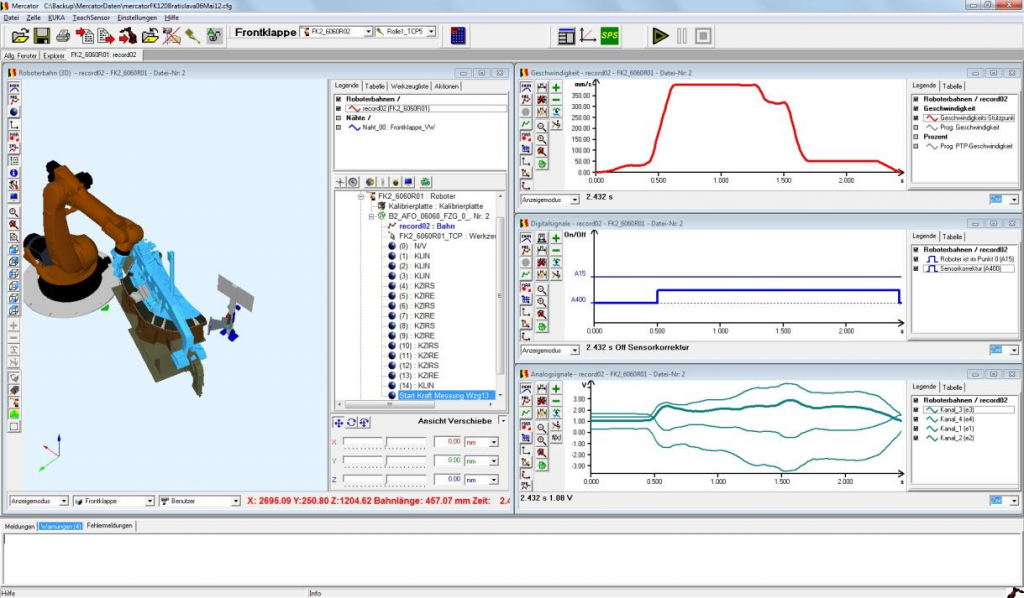

The robot trajectory is displayed in a 3D window as a colored tube together with additional CAD data such as parts and fixtures. Even the robot is displayed as a 3D object and animated by use of kinematics and by that helps the visualization of robot position, movement and speed. The correlated cursor and additional marker functions help with simple and efficient analyzing. It is possible to load several robot paths to the same window and thereby compare changes and their effects.

A layout manager helps defining window positions and settings and all displays could be printed for documentation.

For file management the basic package is equipped with the Mercator-Explorer. Additional to a display of the actual configuration in a tree structure all files could be sorted and filtered in any order.

Technical Requirements:

- Operating System: Windows 7, 8 (Windows 10 or older versions (2000, XP, Vista) on request)

- Processor: min. 1GHz

- Graphic Board: min. 256 MB RAM, DirectX ® 9 support

- Main Memory: min. 512 MB, 1GB recommended

- Network Interface: Ethernet

Accessories:

- Track-In System

- Further modules of Mercator:

- Viewer

- MercatorMonitor MeMo

- Process Data

- Program Editor FolgenEditor

- Path Programming

- TeachSensor

We also gladly provide you with an offer for a fitting desktop PC or laptop.

Mercator-Viewer

Prod.-Nr.: [010-604-00]

Data Sheets: Download-Center

Request for Quote: click here

Function:

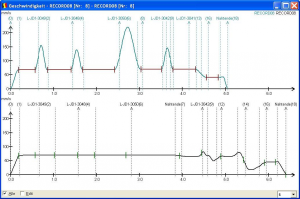

The Mercator Viewer visualizes exactly the robot trajectories. The robot trajectory contains the following four data types:

- Position: path in XYZABC-Data with set and actual values

- Speed: behaviour of programmed and actual speed

- Digital signals: exact display of switching signals time or distance related

- Analog signals: exact display of process signals time or distance related

Each of these data sets is displayed in a seperate window in Mercator. The cursor in all windows is correlated to help with the best overview. Zoom and marker functions enhance the analyzing. The prerequisite for the visualization is a so-called ASCII interface of the respective controller.

Technical Requirements:

- Operating System: Windows 7, 8 (Windows 10 or older versions (2000, XP, Vista) on request)

- Processor: min. 1GHz

- Graphic Board: min. 256 MB RAM, DirectX ® 9 support

- Main Memory: min. 512 MB, 1GB recommended

- Network Interface: Ethernet

Accessories:

- Track-In System

- Further modules of Mercator:

- Mercator Basic Package

- MercatorMonitor MeMo

- Process Data

- Program Editor FolgenEditor

- Path Programming

- TeachSensor

We also gladly provide you with an offer for a fitting desktop PC or laptop.

Mercator Program Editor (Folgeneditor)

Prod.-Nr.: [010-605-10]

Data Sheets: Download-Center

Request for Quote: click here

Function:

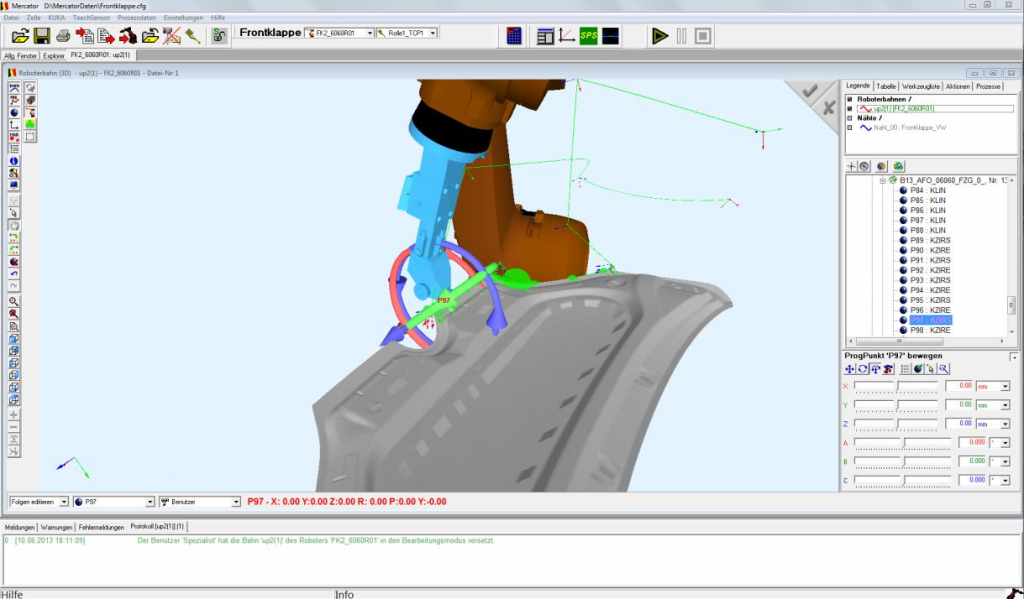

The Mercator Program Editor is a software module of MERCATOR to edit robot programs and store them afterwards to be run on the appropriate robot control. It features convenient editing on graphical and numerical base like:

- Point positioning:

- free positioning on the part surface

- exact visualization of part, robot, tool, clamping situation

- Translation and rotation of programmed points

- Marking and simultaneously editing of multiple points

- Editing points based on different coordinate systems

- Erasure of programmed points

- Changing point sequences

- Simple programming of PLC switching commands at the points as well as optimizations

- Automated optimization of point sequences

- Geometry optimization in relation to work space and part environment

- Optimization of tool orientation on robot path

- Optimization of tool speed on robot path

No controller specific knowledge needed to program the robot. Mercator generates a robot program for the respective robot controller.

To get a first impression of cycle time and movement quality, you may display your robot program in a video animation.

Process parameters, e.g. machining speed, are displayed graphically. Display and editing is possible in tables, too.

Technical Requirements:

- Operating System: Windows 7, 8 (Windows 10 or older versions (2000, XP, Vista) on request)

- Processor: min. 1GHz

- Graphic Board: min. 256 MB RAM, DirectX ® 9 support

- Main Memory: min. 512 MB, 1GB recommended

- Network Interface: Ethernet

Accessories:

- Track-In System

- Further modules of Mercator:

- Viewer

- MercatorMonitor MeMo

- Process Data

- Mercator Basic Package

- Path Programming

- TeachSensor

We also gladly provide you with an offer for a fitting desktop PC or laptop.

MercatorMonitor MeMo

Prod.-Nr.: [ 010-602-10]

Data Sheets: Download-Center

Request for Quote: click here

Function:

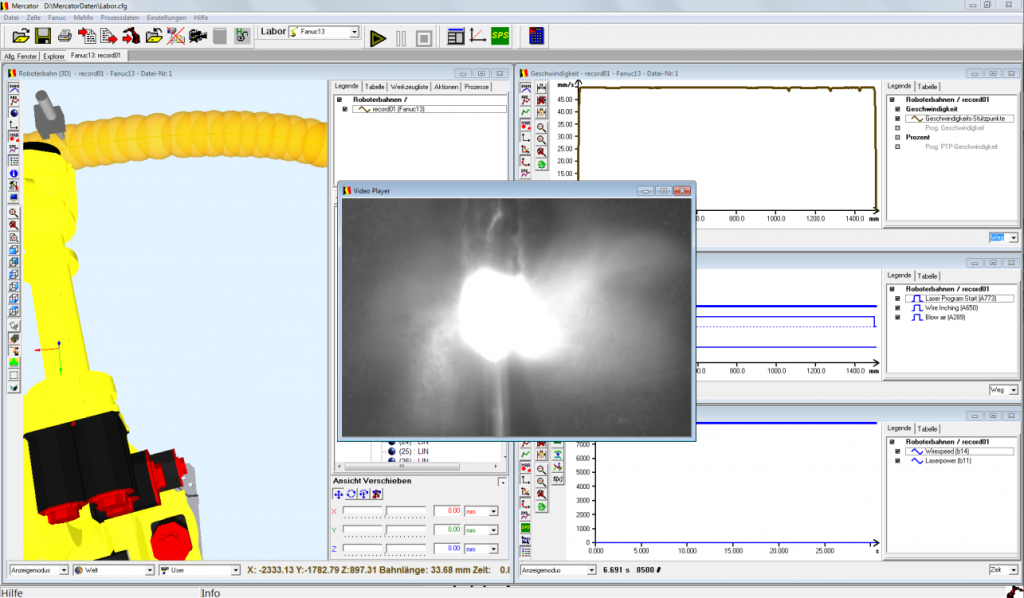

The MercatorMonitor MeMo is the module for recording video data and the path and time synchronious display of this video material with the robot movement as displayed in the mercator software. Required for the recordings called IBGN-Files that contain the robot movement and signal data is a robot controller with IBGN functionality.

IBGN-Files are recorded in an ASCII format making them editable with any common text editor. Mercator additionally allows for an graphical access to that file type.

- Features of the MercatorMonitor are:

-

- Live image display

- Camera switching

- Snap-shot as *.bmp

- Full screen display

- Marker functions, to highlight zones of interest

- Video recorder

- Automatic start/stop video trigger

- Slow motion / still image

- Playback linked to robot program, way related display possible

- Live image display

-

Technical Requirements:

- Operating System: Windows 7, 8 (Windows 10 or older versions (2000, XP, Vista) on request)

- Processor: min. 1GHz

- Graphic Board: min. 256 MB RAM, DirectX ® 9 support

- Main Memory: min. 512 MB, 1GB recommended

- Network Interface: Ethernet

Accessories:

- Track-In System

- Further modules of Mercator:

- Viewer

- Mercator Basic Package

- Process Data

- Program Editor FolgenEditor

- Path Programming

- TeachSensor

We also gladly provide you with an offer for a fitting desktop PC or laptop.

Mercator Process Data

Prod.-Nr.: [010-600-10]

Data Sheets: Download-Center

Request for Quote: click here

Function:

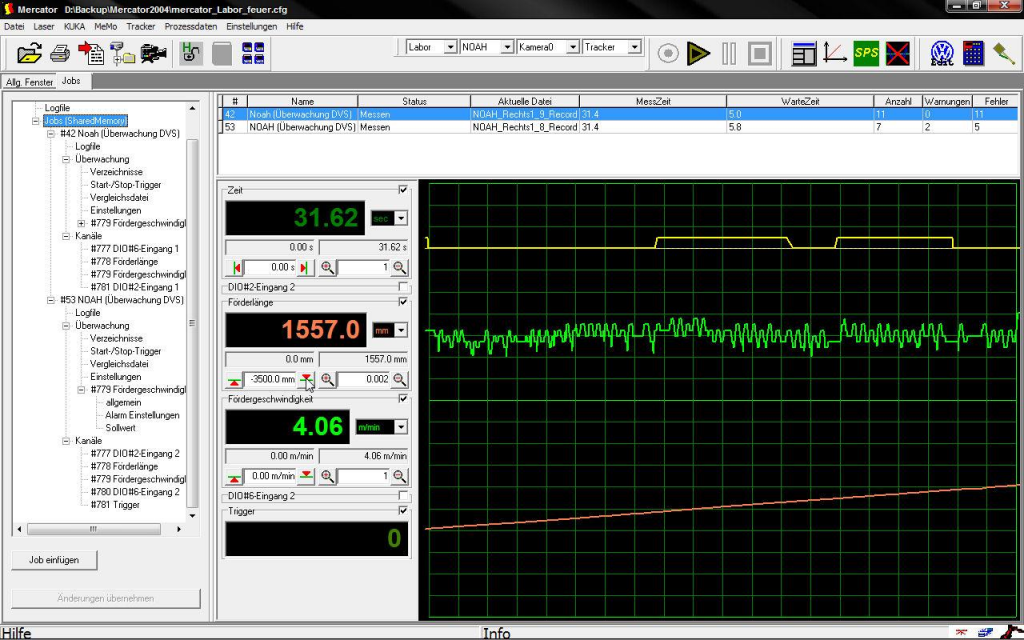

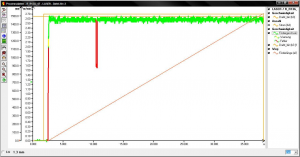

The module Process Data allows the recording, display, analyzing and editing of digital and analog signals. Measurements can be triggered by digital and binary signals as well as analog signal limits. Measuring and evaluation of the signals is defined in jobs. Once the jobs are setup in Mercator they are processed in the background by the data server software, a service program independent from Mercator. Each measurement can be stored with an setable automatic file name.

The Mercator module then allows a display of that data together with the robot path, so that a direct assignment is possible not only over time, but also over the path length. Depending on the connected hardware, different measurement frequencies can be realized. By standard, a Sikora SCU-Box 4.0 switchbox Prod.-Nr.: [010-400-12] is connected. This unit is capable to flexibly measure analog and binary process signals and especially the feeding speed of brazing and filler wire in laser joining processes with a sample rate of up to 1 kHz. For higher sample rates (up to 5 MHz) it is possible to use other USB-sensor heads.

The Process Data module is also capable to do automated evaluations comparing the measured signals with the set values from the robot. The results are displayed in green = OK, yellow = warning and red = error and may be transferred to the system control via outputs.

Evaluation example of the wire feed speed:

Technical Requirements:

- Operating System: Windows 7, 8 (Windows 10 or older versions (2000, XP, Vista) on request)

- Processor: min. 1GHz

- Graphic Board: min. 256 MB RAM, DirectX ® 9 support

- Main Memory: min. 512 MB, 1GB recommended

- Network Interface: Ethernet

Accessories:

- SCU-Box 4.0 Switchbox Prod.-Nr.: [010-400-12]

- Track-In System Prod.-Nr.: [012-601-01]

- Further modules of Mercator:

- Viewer

- MercatorMonitor MeMo

- Mercator Basic Package

- Program Editor FolgenEditor

- Path Programming

- TeachSensor

We also gladly provide you with an offer for a fitting desktop PC or laptop.

Mercator Path Programming (Bahnprogrammierung)

Prod.-Nr.: [010-608-10]

Data Sheets: Download-Center

Request for Quote: click here

Function:

Before using the Mercator Path Programming Module you need to be able to record path and signal data by creating so-called IBGN files. These files will be created by the robot control when writing sets of data in an ASCII format for every IPO-cycle. An IPO-cycle is the smallest computing interval of the robot control and takes from 9 to 13 ms.

IBGN-Files are recorded in an ASCII format making them editable with any common text editor.

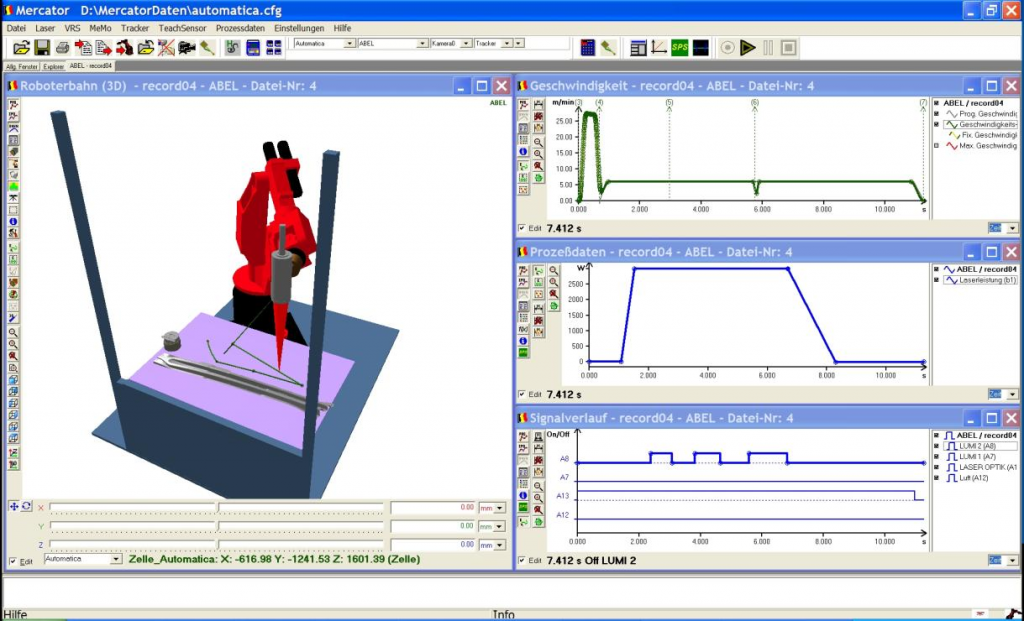

The module Mercator Path Programming allows for the graphical editing of speed, analog and digital signal run of IBGN record files. The IBGN files can be edited by IPO-cycles. This enables an optimized speed and acceleration behavior of the robot on the robot path relating to working process and cycle time.

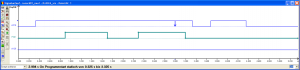

An example for speed optimization is depicted below:

The lower part shows the original speed run of a laser welding application. The upper part displays the result of an Mercator optimization. Set process speed is maintained, while the speed between the process steps is automatically optimized.

PLC signals can be graphically edited, too. For example to generate weld seams all with an exact length. Another benefit is the offline optimization on the Mercator pc during production.

To get a first impression of cycle time and movement quality, you may display your robot program in a video animation. Process params, such as machining speed, are displayed graphically. Display and editing is possible in tables, too.

Technical Requirements:

- Operating System: Windows 7, 8 (Windows 10 or older versions (2000, XP, Vista) on request)

- Processor: min. 1GHz

- Graphic Board: min. 256 MB RAM, DirectX ® 9 support

- Main Memory: min. 512 MB, 1GB recommended

- Network Interface: Ethernet

Accessories:

- Track-In System

- Further modules of Mercator:

- Viewer

- MercatorMonitor MeMo

- Process Data

- Program Editor FolgenEditor

- Mercator Basic Package

- TeachSensor

We also gladly provide you with an offer for a fitting desktop PC or laptop.

❰ Product Overview